Not obtaining regulatory approval for zuranolone to treat a major depressive disorder is a big blow to Sage’s business. That was the one big catalyst it had going and was a key reason Biogen invested in the company back in 2020. Last quarter, for the period ending June 30, it brought in less than $2.5 million from the sale of another postpartum depression drug, Zulresso.

Governments globally are constitutionalizing strict regulations and are penalizing companies that don’t adhere to such laws. Sage X3’s powerful regulatory compliance suite consists of features that will allow you to monitor the new and updated government guidelines and stick to them. With ~$1B in cash, cash equivalents, and marketable securities as of June 30, the company estimates its cash runway will extend through 2026 with funding from partnerships and anticipated revenue. Concurrently, the Cambridge, Massachusetts-based company announced leadership changes.

Top Industries We Serve

In some cases, employees themselves become gatekeepers of information others need, which can cause bottlenecks. With the Sage X3 ERP for pharma industry offers a comprehensive suite of solutions that streamlines the entire process for achieving and maintaining compliance what is sage x3 system with the various regulations. Sage X3 ERP in pharmaceutical industry efficiently manages warehouses by marking them with different codes. They can dispatch them to the required distribution centre or arrange for a pick-up by wholesalers or retailers.

Sage X3 includes a data warehouse, an intelligence engine, and a library of predefined reports that centralizes data then delivers it on demand to the right people at the right time. Additionally, you can expand the core analytics capabilities of Sage X3 with self-service, business intelligence options such as Sage Intelligence and Sage Enterprise Intelligence. For most businesses, critical information, insight, and indicators are scattered about–in spreadsheets, systems, and databases.

Drugmakers could find sympathetic US Supreme Court in drug pricing lawsuits

A full audit trail and archive of historical transactions is maintained for multi-year periods. The fully integrated quality control process rigorously enforces inspections to required characteristics, operational tolerances or expected results. Sage X3 is a very viable choice for a mid-market pharmaceutical manufacturing company. Its many features allow you to meet federal and local governmental regulatory demands with ease. Without that indication, the drug’s peak sales could be between $250 million and $500 million for just postpartum depression, versus $1 billion if a major depressive disorder was also covered. Zuranolone is the first oral drug for postpartum depression, but it was its potential as a treatment for major depressive disorder that had investors bullish on the company.

The sales order is fed in Sales Management System of Sage X3, supplemented with a delivery and sales invoice. Also, maintaining appropriate control over the sales of pharmaceutical products is required by drug law authorities. Sage X3 pharmaceutical manufacturing software has many features like Drug license expiry date, Drug license number, and credit control that allows checking these statutory records conveniently.

Hedge funds’ leveraged trade in Treasury market is drawing scrutiny

Smart manufacturing means automation of processes which readily improves discrete, individual subprocesses. Manufacturing of drugs involve complex individual sub-processes which are difficult to optimize in the absence of an ERP. Customers and regulators alike expect pharma companies to offer complete traceability from sourcing to manufacturing to labeling to distribution.

With the addition of workflow, the status of the project is tied to a person in the company. When entering an order, you can check the inventory of the finished good https://www.globalcloudteam.com/ and the components inventory when the manufacturing order is created. The software can track internal or external development projects and can be attached to quotes.

Need for better quality assurance

There is also a Google-like search capability to find information throughout the system. Sage X3 is integrated with Business Objects and comes with five predefined cubes of data and thousands of metrics that don’t require additional consulting dollars to configure when using the “out of the box” metrics. There are several ERP systems on the market designed to address the specific challenges facing pharmaceutical manufacturers.

The ERP Pharma also offers interactive dashboards for highly transparent statistics and automated processes. Choosing the right cost effective pharmaceutical manufacturing enterprise resource planning (ERP) solution is necessary for any organization that wants to improve visibility, increase efficiency, reduce costs, and improve product quality. While organizations initiate ERP projects for a variety of reasons, a substantial return on investment (ROI) is a motivation for most, if not all, organizations. Why bother gathering data if you don’t have the ability to produce actionable information from that data? Some examples of pharmaceutical-specific reports include reports related to the frequency of expiring products in inventory, quality control test results, and trial. With many packages, you’ll also be given the option of creating custom reports or managerial dashboards.

The job cuts come after the FDA gave only limited approval to the Cambridge company’s new treatment for depression.

Managing the production activities of your company is one of the most crucial steps in achieving product traceability. Functionality within production planning will allow you to track where each batch is within the manufacturing process. You will be able to set project completion dates and adjust them accurately based on your observations of the progress of each batch. Your product formulas will track raw materials as well as the products those raw materials create. The tracking of raw material lot numbers on the formula provides visibility into which raw materials were used in each finished product batch.

- The composition of drugs requires precise set of formulas to achieve the best medicine which is relative to a set of prioritized constraints.

- The system offers a visual finite scheduling tool that can be used manually, or you can choose to let the system put together the best schedule.

- Its compact software design supports industry-specific processes and provides end-to-end visibility across finance, sales, customer service, purchasing, inventory and manufacturing operations.

- The Pharmaceutical Industry is bound to various stringent rules and regulations due to multiple mergers, tie-ups and acquisitions because different methods and ingredients are used to produce potent lifesaving drugs.

- Volatility profiles based on trailing-three-year calculations of the standard deviation of service investment returns.

- And if you fail to adhere to compliances, you may attract massive fines or risk shutting down your company.

- A module specifically designed to manage quality control activities will give you all the tools you need to ensure you’re delivering the same quality product each time.

A smart Pharma manufacturing industry has capability of real-time data visualizations. Data captured from multiple sources like finished or still-in-production stages can be converted into actionable insights to estimate cost, deliverables, production, raw materials etc. A transparent system enhances visibility across departments by providing tools such as role-based views, real-time alerts and notifications, and real-time tracking and monitoring. Managing inventory is the major aspect of ERP software because finished products in pharmaceutical industries come up with an expiration date. The drugs are delivered on first come first out so that they reach the end consumers before the expiry date. Managing production activities and providing insight into exactly what happened and when it happened is crucial to achieving product traceability.

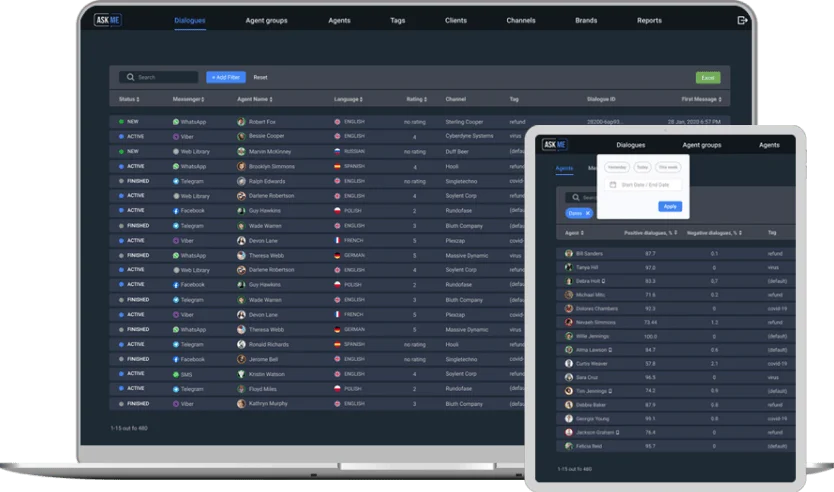

Equip Your Business With the Ability to Easily Manage All Aspects of Sales Workflow.

A pharmaceutical manufacturing ERP must be able to document various ingredients, their storage, the manufacturing process, pH values, particle size, and much more – along with the ability to review it at any given moment. Additionally, the system will need to track any revisions made to the formula, scale it to batches, and more. Further, the system must allow you to set security restrictions to ensure that only users with the authority to make changes can do so. Back-office accounting functionality integrated with your pharmaceutical manufacturing package will encompass features like accounts payable processing, receivables management, financial reporting, and budgeting. If you’re running R&D projects, you’ll be able to track project costs through cost accounting features.